Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic widely used in various industries for its excellent transparency, durability, and ease of fabrication. One of the most common techniques employed to mold acrylic into different shapes is heat bending. This process involves carefully heating the material to its softening point and then bending it into the desired form. In this article, we will explore the fascinating process of heat bending acrylic and the factors that contribute to its success.

- Understanding Acrylic’s Properties:

Acrylic is a rigid and transparent material at room temperature. Its melting point is relatively low compared to other plastics, making it suitable for heat bending processes. When heated, acrylic starts to soften and become pliable, allowing it to be shaped into various forms without losing its structural integrity or optical clarity.

- Tools and Equipment:

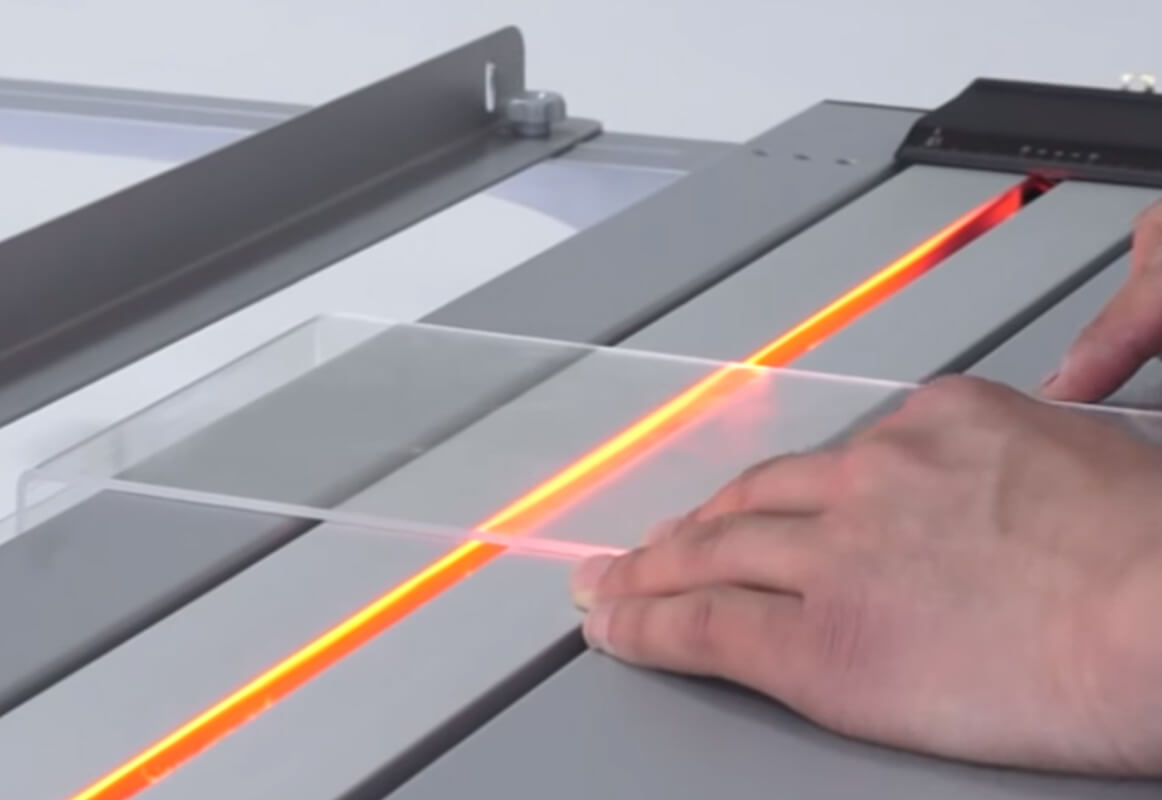

To achieve precise and consistent heat bending results, specific tools and equipment are required. A typical setup consists of a heat source, such as a strip heater or an oven, and a bending jig or mold. The strip heater emits controlled heat, which is directed at the specific area that needs bending, while the bending jig provides the acrylic with the desired shape during the heating process.

- Heating Process:

The success of heat bending acrylic lies in the careful and controlled heating of the material. If the acrylic is heated unevenly or to an incorrect temperature, it may lead to undesirable outcomes such as distortion, cracking, or even complete failure of the bending process.

The heating process generally follows these steps:

a. Measuring and Marking: The acrylic sheet is measured and marked to indicate the bending area accurately.

b. Preparing the Heat Source: The strip heater or oven is set to the appropriate temperature, depending on the thickness and type of acrylic used.

c. Heating the Acrylic: The marked section of the acrylic sheet is exposed to the heat source until it reaches its softening point. The temperature must be carefully monitored to avoid overheating.

d. Bending: Once the acrylic is sufficiently heated, it is carefully placed into the bending jig or mold. Pressure may be applied to ensure a tight fit against the mold, especially for complex shapes.

e. Cooling and Setting: After the acrylic has taken the desired shape, it is left to cool and solidify, retaining the new form once it reaches room temperature.

- Factors Affecting Heat Bending:

Several factors influence the heat bending process and the final outcome:

a. Temperature: The right temperature is crucial to soften the acrylic without causing it to become too pliable or lose its structural integrity. The optimal temperature varies based on the thickness and type of acrylic being used.

b. Thickness: Thicker acrylic sheets generally require higher temperatures and longer heating times to achieve proper softening.

c. Type of Acrylic: Different types of acrylic may have varying softening points and thermal properties, necessitating adjustments in the heating process.

d. Bending Jig Design: The bending jig should be carefully designed to match the intended shape, providing support during the bending process.

e. Heating Time: Overheating or underheating the acrylic can lead to deformation or failure in maintaining the desired shape.

- Applications of Heat Bending Acrylic:

The ability to heat bend acrylic into various shapes has opened up a wide range of applications across industries, including:

a. Architecture and Interior Design: Curved acrylic sheets can be used for skylights, architectural features, and unique interior decor elements.

b. Display and Signage: Heat bending allows the creation of eye-catching displays, 3D signage, and custom-shaped retail fixtures.

c. Automotive and Aerospace: Acrylic can be bent into complex shapes for vehicle windshields, airplane windows, and aircraft canopies.

d. Medical and Scientific: Heat-bent acrylic is used in laboratory equipment, medical device components, and protective barriers.

Conclusion:

Heat bending acrylic is a fascinating process that allows this versatile material to be transformed into diverse shapes for numerous applications. The precise control of temperature and the use of specialized tools are vital in ensuring successful outcomes. With its exceptional optical properties, durability, and ease of fabrication, heat-bent acrylic continues to play a significant role in shaping the world around us.